PLASTIC INJECTION MOLDING

About company

Injection moulding

Manufacture of plastic products by injection moldingMould design

We will help you place an order for the manufacture of molds from our trusted partners

Mould testing

In conditions close to those in which it will be usedСrushing of production waste

Crushing waste plastic significantly reduces the cost of productionOur equipment

Horizontal injection molding machines

The horizontal injection molding machine has a number of advantages and produces high productivity. Our injection molding machines have the ability to cast glass-filled plastics.

Product Weight: min 20 gram, max 700 gram.

Cost:

- for products up to 340 grams ~ price on request

- for products from 340 to 700 grams ~ price on request

Mold testing ~ price on request

Vertical injection molding machines

Syringe press with electronic control

Vertical injection molding machine is suitable for small-scale and large-scale casting, it allows the use of pre-hardened elements. For example, an electric plug, tools with plastic handles, etc.

Product Weight: min 1 gram, max 120 gram.

Cost:

- price on request

Mold testing ~ price on request

Moulds

The number of cavities incorporated into a mould will directly correlate in moulding costs. Fewer cavities require far less tooling work, so limiting the number of cavities in-turn will result in lower initial manufacturing costs to build an injection mould.

As the number of cavities play a vital role in moulding costs, so does the complexity of the part's design. Complexity can be incorporated into many factors such as surface finishing, tolerance requirements, internal or external threads, fine detailing or the number of undercuts that may be incorporated.

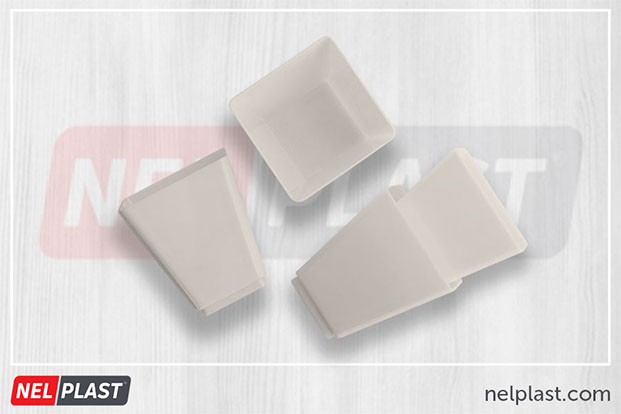

Examples of products manufactured by NELPLAST

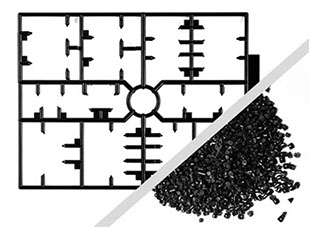

Waste crushing

The crushing of plastic waste is an extremely important branch in the polymer industry, it substantially reduces the cost of production, since the rejected products can be used again as an additive to primary raw materials.

Test injection molding

Mold testing

Support of selection of material

Our partners

Anyone who has an idea about the production of plastic products and their implementation, can order from us a full range of services - from the sketch to the finished product. We assist in the design, selection of materials and placing an order for the manufacture of molds for injection molding machines. This will allow you to reduce the cost of purchasing expensive equipment, as well as avoid the risks associated with the technological process.

We guarantee an individual approach to everyone, our efficiency, price and quality will pleasantly surprise you!